Customized Silicone LED Light Strip Cover China Supplier

Meiji Lighting is a manufacturer and supplier that develops and produces silicone light strips in China. With years of research and development, sales and market conditions in the industry, here are some hot-selling styles recommended for your reference.

1010 LED Silicone Light Outline

12*12MM LED Silicone Light Cover

1616 LED Silicone Light Strip Channels

20*20MM Silicone Strip Diffuser Light

6*13MM Silicone Light Diffuser DIY Strips

0815 Flexible LED Silicone Channel Lighting

8*17MM Silicone Light LED Channel System Stripe

D26 Round Silicone Tube For LED Strips

What is LED Silicone Light Strip cover

LED Silicone Light Strip Cover is a flexible protective shell made of silicone that is used to wrap and shield LED light strips. This protective cover has multiple purposes, including increased durability, flexibility, improved aesthetics, and environmental protection for LED lights.

What Are Silicone LED Light Strips Cover Components

Structural Components of Silicone Light Strips

Silicone light strips consist of several key components that contribute to their functionality and durability:

LED Chips: These are the core light-emitting diodes that generate the light. They are embedded in a flexible substrate.

Silicone Encapsulation: A transparent silicone layer that encapsulates the LED chips, providing protection against moisture, dust, and mechanical impacts.

Flexible Substrate: Typically made from FPC (Flexible Printed Circuit), this holds the LED chips in place and allows the strip to be bendable.

Copper Trace: Electrical pathways that connect the LED chips, allowing them to be powered uniformly.

Adhesive Layer: A self-adhesive backing allows for easy installation on various surfaces.

Connectors: Specialized ends for power supply and daisy chaining multiple strips.

Driver/Controller: External components that regulate voltage and offer control over light intensity and color.

Where will silicone led light strips be used?

Silicone light strips are versatile and find use in multiple sectors, particularly appealing to B2B buyers like hotel lighting purchasers or advertising lighting buyers. Here are some common Applications:

Indoor Lighting: Ideal for mood lighting, under-cabinet illumination, and architectural accents.

Outdoor Lighting: Often used in signage, landscape lighting, and façade lighting due to their weather-resistant properties.

Industrial Use: Employed in machinery lighting and in places requiring robust, moisture-resistant lighting solutions.

Hospitality: Commonly used in hotels for accent lighting, stairway illumination, and outdoor patios.

Retail and Advertising: Used in display lighting, billboard illumination, and retail window

Silicone vs. Neon LED Light Strip Differences

Choosing between the two will depend on your project’s specific needs, including factors like location, required luminosity, and budget.

1.Material

Silicone Strip: Made of flexible silicone, allowing 2.Intricate Designs.

Neon Strip: Usually made from PVC, making it sturdier but less flexible.

3.Application

Silicone Strip: Great for indoor use, intricate layouts, and tight corners.

Neon Strip: More suited for outdoor applications, commercial signage, and impactful visual installations.

4.Durability

Silicone Strip: Moisture and dust resistant.

Neon Strip: More durable and can withstand harsher conditions.

5.Light Output

Silicone Strip: Provides a softer, more uniform light.

Neon Strip: Offers bright, vibrant illumination, perfect for capturing attention.

6.Cost

Silicone Strip: Generally more cost-effective.

Neon Strip: Tends to be pricier due to enhanced features and durability.

Advantages of LED Silicone Light Strips Cover

Flexibility:

Silicone led strips are highly bendable, making them ideal for intricate designs and challenging installation spaces, where SMD and COB might not be as versatile.

Durability:

They are resistant to moisture and dust, offering longer lifespan compared to traditional neon lights, which can be beneficial for long-term projects.

Uniform Light Output:

Silicone Strip lights provide consistent, smooth illumination, unlike SMD or COB, which can sometimes create hotspots.

Safety:

Lower operating temperatures compared to neon lights, reducing potential fire hazards.

Ease of Installation:

Lighter and more manageable than neon strips, they offer a user-friendly setup that could save time and labor costs.

Cost-Effectiveness:

Generally less expensive than COB and Neon lights, providing a competitive pricing advantage without compromising on quality.

Choosing LED Silicone Strip lights can offer businesses a balanced combination of flexibility, durability, and cost-efficiency, aligning well with diverse project requirements and client needs.

Ensuring Quality in Silicone LED Light Strips Cover

Torque testing

Pull-toggle test

Bending Test

Environmentally friendly materials

Needle Flame Test

Acid-Base Test

Dust Test

Waterproof testing

UV testing

How To Install Silicone LED Light Strip

Flexibility: Silicone strips are highly bendable, making them ideal for intricate designs and challenging installation spaces, where SMD and COB might not be as versatile.

Durability: They are resistant to moisture and dust, offering longer lifespan compared to traditional neon lights, which can be beneficial for long-term projects.

Uniform Light Output: Silicone Strip lights provide consistent, smooth illumination, unlike SMD or COB, which can sometimes create hotspots.

Safety: Lower operating temperatures compared to neon lights, reducing potential fire hazards.

Ease of Installation: Lighter and more manageable than neon strips, they offer a user-friendly setup that could save time and labor costs.

Cost-Effectiveness: Generally less expensive than COB and Neon lights, providing a competitive pricing advantage without compromising on quality.

Choosing Silicone Strip lights can offer businesses a balanced combination of flexibility, durability, and cost-efficiency, aligning well with diverse project requirements and client needs.

Meiji Lighting goes the extra mile

No more endless time wasting on bad wholesalers. Our goal is to give you peace of mind. We are responsible for all aspects of raw material testing, production, in-production quality inspection, bulk aging testing, semi-automatic packaging and after-sales. Our consultants will provide you with the latest information every step of the way.

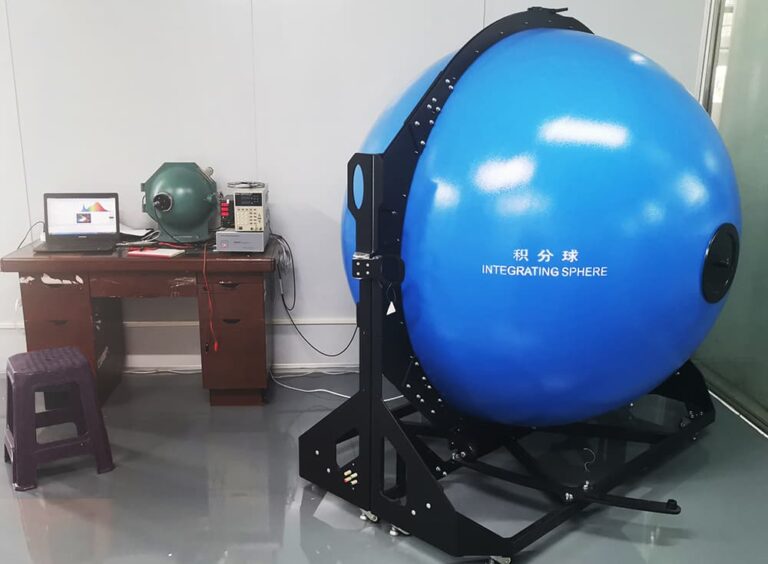

Integral Ball

Oven

Wind Shower Room

Automatic Tin Brushing Machine

Automatic Patching Machine

Reflow Welding

Semi-Finished Product Test Bench

Cutting PCB Machine

Automic Welding Machine

Dropping Glue Aging Area

Semi-Automic Packageing Machine

A Corner of the Finished Goods Warehouse

FAQs About Meiji Lighting

We cooperate with well-known LED chip brands in the market, such as Cree, Nichia, Osram, etc.), which are well-known for their superior technology and reliability.And in case if you have special needs, like Samsung, Nichia, Tridonic, Soul, Citizen etc., we can also help.

Our production time is typically 5-15 days, but can be longer for larger quantities or customized orders. Express shipping ensures faster arrival, while container cargo takes 15-60 days. Contact us for rush orders and specific timing.

MeiJi Lighting is a ISO 9001 approved lighting manufacturer. Most of our lamps have CE and RoHS certificates.If you need other certificates for your projects or market, like UL,ETL,ENEC, SASO, BIS, etc. We can also help.

- Website Contact Form (Any red button on the website)

- Direct Phone Inquiry

- Exhibitions

- Google ADS

Yes. We have an experienced design team and technical experts who can customize and develop unique indoor&outdoor lighting solutions according to your project requirements. You can go to our project case to see and contact us!

1.Faulty Electrical Connections: The Leading Issue

Poor Soldering: Weak soldering points can lead to intermittent or complete loss of lighting.

Loose Connectors: Connectors that aren’t properly secured can result in unstable electrical connections.

2.Signs of Faulty Connections

Intermittent Lighting: The strip might flicker or sections might go dark temporarily.

Inconsistent Brightness: Some sections may appear dimmer than others.

No Power: The light strip fails to turn on altogether.

For our low voltage lighting fixtures, a constant voltage power supply is necessary. To ensure a longer lifespan, we recommend choosing a power supply with a loading capacity approximately 20% higher than the actual requirement. For instance, for a 10-meter LED Strip Light (12W/m), a 150W power supply is preferable.

MeiJi offers a range of double-sided tape solutions for LED strips, tailoring to various scenarios. Our selection includes 3M tapes like 200MP, 300MP, 9080, VHB 5608N, tesa 4965, and blue thermal tape, ensuring versatile options for different needs.

Our regular products come with a 3-year warranty, while special requirements or customized products have a warranty of 3-5 years. We ensure reliable coverage and support for our customers’ specific needs and offer extended protection for tailored solutions.

We know that the number of lamps required for each project is uncertain. If customized products, We can produce according to the quantity you need. There is no minimum quantity requirement. Of course, if the quantity is large, the price will be more favorable.

Solutions for Common Problems

1. Check Power Supply and Electrical Connections

Symptom: No power or illumination.

Action: Verify the power supply is functional and correctly rated for the strip light. Ensure all connections are secure and properly soldered.

2. Inspect LED Chips and Circuitry

Symptom: Flickering or sections not lighting up.

Action: Examine the LED chips for any visible damage. Use a multimeter to check the circuit continuity. Replace damaged sections or LEDs as needed.

3. Address Overheating

Symptom: Dimming or color changes.

Action: Ensure the silicone strip light is adequately ventilated. If it’s installed in a confined space, consider adding heat sinks or cooling fans.

4. Validate Controller Settings

Symptom: Irregular lighting patterns or colors.

Action: Ensure the controller is correctly programmed and not damaged. Perform a factory reset or software update if necessary.

5. Replace or Repair Components

Symptom: Persistent issues despite above-mentioned checks.

Action: Consider replacing the silicone strip light or specific components like the power supply or controller.

Yes. You can get the free 5M samples before you place an order . You need to provide the receiving name ,address and phone number and express delivery account number .

We’re more than just a supplier; we’re your partner in growth. Contact us today and let’s work together to double the profits for your next project.